Application of high-speed dispensing machine in fingerprint

作者:点胶机厂家 日期:2019-08-01 14:58 浏览:

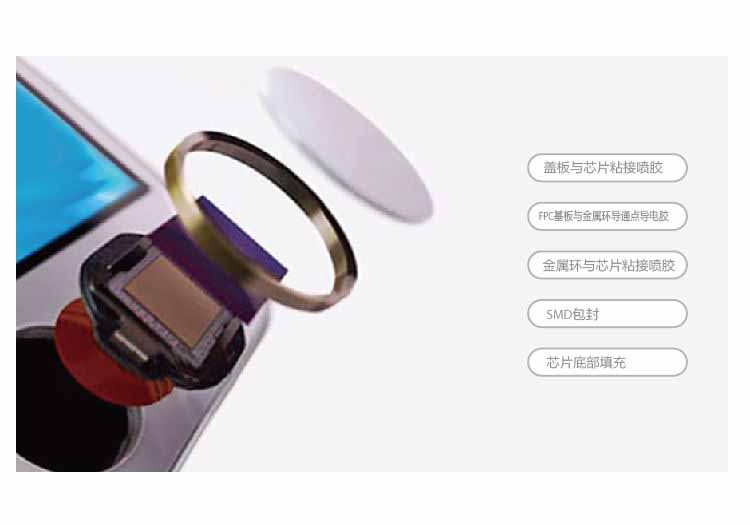

At present, the structure of fingerprint recognition in the market mainly has four main solutions: front and back pressing, front and back sliding. In the process of dispensing, we usually point UnderFill glue around the chip. Commonly used glue images such as 3808, 3806. The fingerprint identification dispensing process is to apply a proper amount of conductive paste on the gold finger of FPC.

Fingerprint identification structural dispensing

There are two main processes in the process, one is to adopt the structure of patchwork, the other is to cut into small plates, and then to dispense glue. One of the whole process is mounting, placing, reflow welding, preheating, and then solidifying. Common fillers are single-sided high-speed dispensing machine, or L-type including C-type. At present, for fingerprint identification, we usually use four-sided dispensing mode to complete surface dispensing.

Non-standard high-speed automatic dispensing machine

The basic requirements of the process are as follows: first, all sides must be dispensed with glue evenly to achieve adhesion; second, the distance between one side is less than 0.4 mm; third, glue is greatly affected by environmental factors; fourth, there should be no voids or bubbles at the bottom, and UPH should be greater than 1500. .

Feeding method is usually the whole way of feeding pressure barrel. One of the main solutions is to adopt the mode of fully automatic high-speed dispensing machine, including dispensing machine with feeding and unloading system, then use dispensing valve, inject valve and select suitable dispensing valve, including fingerprint identification dispensing process with laser sensor.

Standard automatic high-speed dispensing machine

The whole work flow is that the operator's feeding pressure barrel is placed on the machine table, the material is automatically pushed up and fed, the PCB plate is heated, then the CCD recognizes and sprays the dispenser, sprays the dispenser, then the PCB insulates, then pushes the material and cuts the insulated pushing material to complete the whole set of fingerprint identification application.